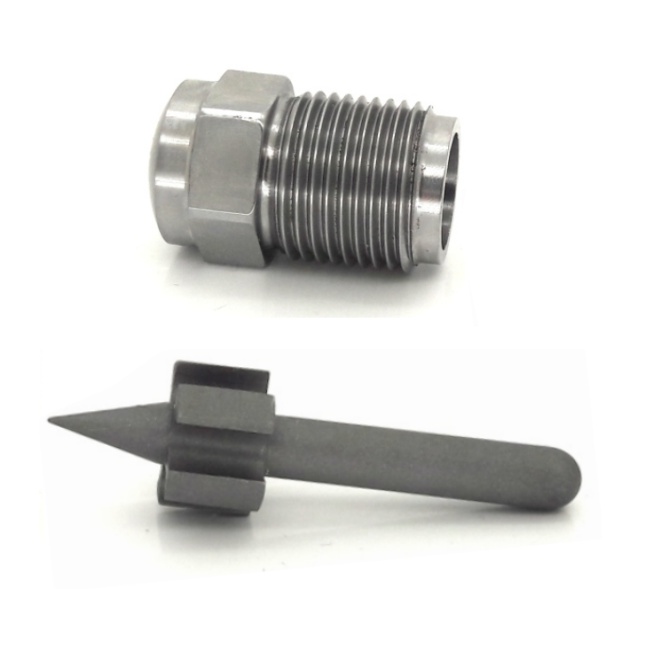

Anti-Drool Nylon Tips with Spreader Insert

- Reduces Nylon Material "Drooling" and "Freezing Off"

- Reduce Nozzle Temperatures

- Fits Standard 7/8" RT Nozzles

- Thread: 7/8" UNF

- Fast Cycle Times

£199.00 – £199.00 + Vat

Description

As all moulder know viscous materials such as Nylon can cause ‘Drooling’, ‘Stringing’ and ‘Freezing Off’ between moulding cycles.

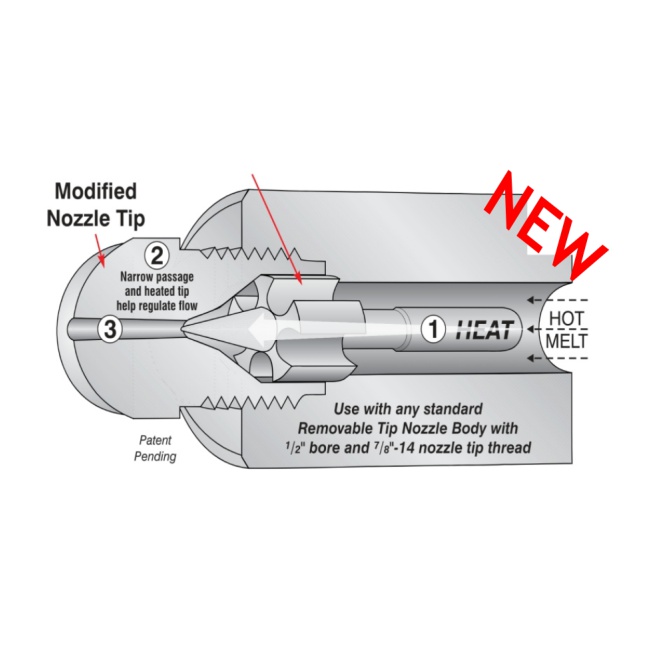

This nozzle tip and spreader insert offers a unique design that helps control heat dispersion and metering of the polymer flow offering a clean sprue break.

Nozzle temperatures can be reduced as the need to over compensate with more heat to stop freezing off can be eliminated.

The Anti-Drool tip can stop costly cold slugs forming.

Based on our standard removable nozzle tips it has a special internal profile to work with the spreader but will fit all standard nozzle with a 7/8-14 UNF thread.

How it works

1. Spreader body extracts heat from polymer in nozzle body and transfers to spreader tip.

2. Creating a narrow passage at rear of nozzle orifice the size of the passage and heat from the spreader lets you precisely control melt temperature through that critical area, avoiding both ‘Freeze-Offs’ and ‘Drooling’

3. The remaining nozzle orifice cools freely allowing a clean break with minimal stringing.

Why Buy?

- Prevents Drooling, Stringing & Freezing Off

- Lets You Reduce Nozzle Temperatures

- Run Faster Cycles

- Eliminates Dangerous & Problematic Cold Slugs

Technical Details

Tip: Polished chrome vanadium steel

Hardness: 48-52 Hrc

Spreader: H13

Hardness: 46-48 Hrc

Filled Material: Tested with filled material <30%